out of stock

$2,805.00

-

Out of stock

$35.00

$35.00

The All-New industry leading WoodMaxx MX-8500G+ direct drive gravity feed USA made wood chipper is packed with features that are so unique it stands alone in its own class. Perfect for cleanup of branches 5″ diameter or less. Designed with the sub-compact tractor owner in mind (but can be used on any cat-1 tractor), this wood chipper comes in under 425lbs but boasts a heavy duty 3/4” thick structural steel flywheel. We’ve engineered the perfect mix of simplicity with innovation to deliver a wood chipper that requires no powered infeed system, belts, jackshafts, or hydraulics yet it offers excellent performance and efficiency. “G” stands for gravity, the “+” represents the sum of the engineered features that make the MX-8500G+ superior to all others.

WoodMaxx patented MX-Series wood chippers are proudly designed, engineered and manufactured in the USA at our Akron, NY facility. With a multi-million-dollar investment in the latest high-tech fabricating equipment to increase production, WoodMaxx MX-Series wood chippers are in high demand.

As shown in customer videos, this chipper pulls material flawlessly, without any resistance, which leads to one of our most common customer questions. How is this possible and what allows for such efficiency, speed, and power? This has to do with the patent pending rotary anvil, which assists in feeding material to create less friction, allowing for a smooth transition from log to chips. The engineers thoughtfully chose the angle of the chipper knives as well, so you’ll notice they’re angled rather than perpendicular, like our hydraulic chippers. This knife design enhances the chipping experience since it gives the logs the opportunity to immediately catch the sharp edge of the knives for a seamless pull.

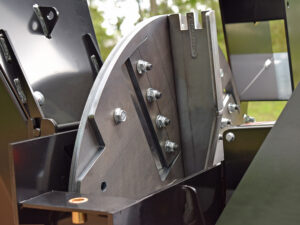

This innovative WoodMaxx patent pending Rotary Anvil design increases material infeed efficiency. All other chippers on the market include a flat edge stationary anvil which acts as a lower cutting edge in conjunction with the flywheel knife, similar to the blades on a pair of scissors. This function shears the wood material clean off, releasing the wood from the inward pull of the rotating flywheel. Although this is acceptable for a chipper that utilizes a powered infeed system, it is not ideal for a gravity feed chipper. WoodMaxx patent pending cylindrical anvil prevents the material from being sheared off completely upon first strike. This action causes the flywheel knife to pull the wood material downward around the radius of the spherical anvil increasing the pulling effect of the wood material into the chipper which greatly increases the chipping efficiency. You will not find this feature on any other wood chipper on the market.

The WoodMaxx MX-8500G+ requires a tractor with a category 1 or 2 three-point hitch and at least 15 HP at the PTO. Chipping capacity is directly related to horsepower and torque, therefore with 15 HP you can expect to chip 3″ hard wood and 4″ soft wood. With 50+ HP you can expect to chip any material up to 5″ in diameter with no trouble.

Immediately after material is fed into the chipper, the 110 pound structural steel flywheel gets right to work. The dynamically balanced 24” diameter flywheel is coupled with a 1-3/4” main shaft supported by two industrial grade 4-bolt flange bearings ensuring that the flywheel runs smooth and true, greatly reducing vibration.

Equipped with four (4) USA made A8 hardened tool steel knifes mounted on an angle increases the effective cutting edge projection and the effective pull of material into the chipper head. Bigger projection=Bigger bite=more work in less time. These knives are attached to the flywheel with made in USA Holo- Krome class 12.9 bolts. The reversible knives means that you get twice the work out of one set! With 4 total knives, the work is equally divided by 4 times, prolonging knife life while still boasting 36 strikes every second. Click here to learn how long your chipper knives will last.

The MX-8500G+ is manufactured with a 5” wide flywheel housing to make room for the extra tall flywheel fins. These extended fins are designed to increase airflow in the flywheel chamber to help evacuate all those chips to right where you want them.

The MX-8500G+ is an addition to our direct drive line-up. The premium PTO shaft (included in purchase) from your tractor hooks directly to the input shaft of the flywheel. This results in the most efficient transfer of torque and power as there are no intermediate components such as belts for torque to be lost. The WoodMaxx 8500G+ is designed for use ranging from 540-1100 PTO RPM.

At only 42” (waist height) high, the infeed bin quickly slopes downward leaving gravity to do the rest. This slope is paired with our rotary anvil and angled flywheel knives to provide optimal infeed ability. Don’t believe us? Have a look at some of our videos and see it for yourself.

The WoodMaxx MX-8500G+ wood chipper offers a large 24” x 24” infeed opening that funnels down to 8” wide x 8″ high flywheel opening. Note- ( flywheel opening is 8″x8″, but will only accept 5″ material because of the sloped infeed angle in relation to the flywheel opening.)

WoodMaxx MX-series wood chipper knives can be changed easily by one person in as little as 10 minutes. The entire top of the blower housing opens like a clam shell. This allows for easy access to the flywheel and knives.

California Residents See Prop 65 WARNINGS

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.

Sorry, no reviews match your current selections

© 2022 WoodMaxx Power Equipment Ltd. All Rights Reserved.

I choose the Woodmax MX-8500G+ because I didn’t want to deal with a hydraulic drive system. I was concerned that it might not work that well but for my small property and variety of tree types but I have been pleasantly surprised it works great. It has also done well on older dried wood but certainly shines on fresh cut wood. I have easily done russian olive branches up to 5 inches in diameter and juniper and pinion branches 4 inches in diameter. I’m not sure how the blades will hold up but I have done about 10-12 of chipping and so far the blades appear to still be functioning well. This is a piece of equipment that I will probably use 4-6 times a year so it being compact and easy to just set down and store it a plus. I was a skeptical purchaser but now a very happy owner. Jan

works great. no issues. I’m using a Mahindra 1626 with 19 hp at the pto. great investment

Great machine. I have used for about one year. Eats up branches and small trees. Have it on my John Deere 1025R. Feeds fantastic. Gravity and cutters pull branches in without having the expense and complication of a power feeder. When exhaust chute jams up, it means the knives need to be sharpened. About a minute per side on a belt sharpener and it works perfectly. Great customer service!!

I’m very impressed with the gravity feed. I was skeptical but the shoot is angled downward towards the wheel and it eats exactly how it should. I rented a 6-in chipper on a trailer to compare with an auto feeder and the 8500g+ outperformed it. If something ever gets jammed in the 8500g+ it takes almost no time to shut it down and open up a part to unclog it and get back to chipping. It will also take a 6 inch fresh pine branch along with the same size hickory.

I have a John Deere 4100 with 16 horsepower at the rear PTO and it performs great!

The assembly when it arrived was easy and very self-explanatory. The only modification I needed to do was to cut the drive shaft about 2 in. There are videos on the internet to help make it super easy.

Works great with my old Ford 641 tractor! I’ve chipped pine and cedar up to about 5″ and various hardwoods up to about 4″ with no difficulty. Having used only hydraulic feed self-powered (25 horse Kohler) chippers before I’d say this is no better or worse, just different. It feeds large material faster at times, but is less reliable at pulling in clumps of small branches without some help (think all the separate tops of branches left over after you feed a full tree). The only reason I rated it 4 star and not 5 is I had to buy a quick hitch just to space the chipper further away from the tractor or the PTO shaft would have been too short. If my old Ford didn’t require an over-running clutch coupler on the PTO shaft it might have been fine without the quick hitch.