Subtotal: $350.00

Subtotal: $350.00

$8,855.00 – $10,475.00

-

The WoodMaxx MX-9900ss is a robust, self-feeding skid steer mounted auto-feed wood chipper that’s built to withstand commercial use. This extremely compact chipper utilizes a patent pending hybrid hydrostatic drive infeed system, instead of using the hydraulic oil from the skid steer to drive the infeed roller. This system generates significantly less heat which allows for a more efficient and powerful skid steer chipper. Some prominent features that enhance the MX-9900SS’s performance are the high torque White (USA) brand hydraulic motors and 4 high quality (A8 tool steel) made in the USA knives which are standard on all MX-series chippers. Since all skid steers have different oil flow and cooling abilities, we also offer an optional oil cooler. The design of the WoodMaxx MX-series wood chippers is so unique and innovative that it is now patent pending.

WoodMaxx patented MX-Series wood chippers are proudly designed, engineered and manufactured in the USA at our Akron, NY facility. With a multi-million-dollar investment in the latest high-tech fabricating equipment to increase production, WoodMaxx MX-Series wood chippers are in high demand.

POW-R-TORQ™️️ is a trademarked and patented infeed system. This system is a combination of our patented hydrostatic pump motor, specially designed infeed roller, nitrogen filled gas springs, automatic belt tension device and American made A8 tool steel knives. Combined, these features create the most powerful, efficient and speed variable infeed system available on ANY wood chipper on the market today.

Hydrostatic drive systems have several differences and benefits over traditional hydraulic drive systems. Hydrostatic pumps exhibit variable displacement without the need for external devices such as flow control and flow diverter (proportioning) valves. This reduces the number of fittings, hoses, and amount of oil needed. Unlike hydraulic systems requiring several gallons of oil, our hydrostatic system only needs 2 quarts of motor oil (Why can’t I use synthetic oil in my chipper? Click here to find out) Hydrostatic technology has been around for decades and is used in some of the highest demanding and harshest mobile applications such bulldozers, trains, excavators, skid steers, and even ride on lawn mowers. Hydrostatic systems are very efficient, generate minimal heat, and are extremely precise, allowing for smooth infeed speed control from 1 ft./min to a full 75 ft./min. with full power through the entire speed range. Take a look below for more information on each of these key POW-R-TORQ™️️ features or watch a short video here.

WoodMaxx MX-9900ss wood chipper comes shipped to you in in a wooden crate and is 100% completely assembled. Simply attach the MX-9900ss wood chipper to your skid steer, lower the infeed bin, raise the discharge chute, and fill the hydrostatic oil reservoir with two quarts of 10W-40 motor oil. The WoodMaxx MX-9900ss wood chipper is manufactured and assembled right here at our facility, assembled by American workers, and given a comprehensive 22 point inspection, and is serviced prior to leaving our warehouse. Simply follow the user friendly operator manual and you will be chipping in no time at all.

The WoodMaxx MX-9900ss wood chipper uses a 26.5″ x 1″ dynamically balanced 220 pound flywheel that spins at 1200 RPM to deliver the energy to quickly and easily chip all types of material. Competitors use a wide range of flywheel weights, much lighter in most cases. Through thorough testing and experimentation, WoodMaxx has discovered that the 220 pound 26.5″ flywheel/ 1200 RPM speed is ideal for wood chippers. Speeds in excess of 1200 RPM will simply wear the knives prematurely, and the result is often saw dust instead of wood chips.

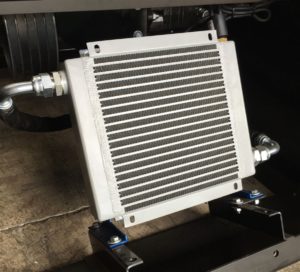

Because all skid steers utilize varying amounts of oil reserve, and have variable cooling capacities we have an optional oil cooler available. This cooler is 12 volt with a built in thermostat that is set at 140 degrees fahrenheit. This feature is not found on any competing skid steer mounted wood chipper, and an important available option to protect your skid steer from over heating.

The WoodMaxx MX-9900SS wood chipper is equipped with a USA-made hydraulic infeed motor. This high quality 200cc orbital motor offers high load bearing capacity, giving it the ability to withstand thousands of hours of rotational resistance, that comes with drawing large, dense material into the infeed bin. It also offers extremely high torque for maximum pulling efficiency.

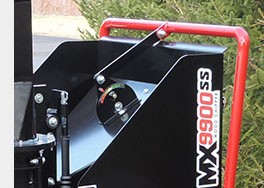

The WoodMaxx MX-9900SS Skid steer Wood chipper attachment is equipped with a built in electronic tachometer/ hour meter. Since all skid steers put out varying oil flow, it is difficult to determine if the proper flywheel speed is achieved, so we have added a digital tachometer. Simply engage the oil flow from your skid steer to the chipper at idle and throttle up until the meter reads 1200. This feature ensures that you run the chipper at the optimal speed without guessing. Additionally, the hour meter takes the guess work out of maintenance intervals.

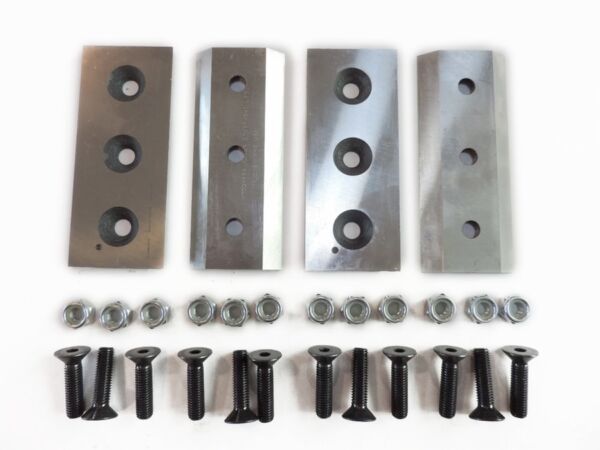

The WoodMaxx MX-9900 American-made wood chipper is equipped with four USA made and offset, reversible dual edge knives installed. These knives are attached to the flywheel. Four knives, and they are offset so that with every 90 degrees of rotation, the knife is taking a slightly different cut of material. This is equivalent to using a serrated knife to cut bread instead of a straight knife. Ultimately, this feature allows for chipping large material without overworking your tractor. The reversible knives means that you get twice the work out of one set! Designed for extreme-duty – there is no better material than A-8 hardened tool steel for superior performance and life. Click here to learn how long your chipper knives will last.

The WoodMaxx MX-9900ss skid steer chipper attachment is equipped with a universal skid steer mounting bracket that will fit any skid steer that utilizes a corresponding mount.

Since all hydraulic systems require protection from pressure spikes, the WoodMaxx MX-9900ss skid steer chipper attachment is equipped with a built in relief valve to prevent damage to the drive motor.

WoodMaxx MX-series skid steer wood chippers use a high torque hydraulic motor that requires 18-24 GPM, but we do offer a slightly smaller motor for skid steers with as little as 15 GPM as an option. (Please call). Additionally, the torque from the motor is transferred through two sheaves to power the flywheel. This system increase the flywheel speed and allows the belts to absorb shock from the chipper head to reduce stress on the drive motor. This chipper comes standard with 5 extreme duty 5/8″ wide cogged drive v-belts that are made specifically for WoodMaxx . Cogged v-belts run cooler, and transfer more torque than plain smooth v-belts. Although the OEM belts are very high quality, if the need arises, the standard size BX belts allows you to purchase replacement v-belts at any auto parts store.

Safety is paramount on WoodMaxx wood chippers. Located on the top of the infeed bin, the MX-9900ss utilizes an easy to activate hydrostatic auto-feed stop safety bar to disengage the infeed roller in case of an emergency, or to clear the infeed bin if necessary. Simply pull the bar forward to increase the speed, and push if forward to decrease or reverse the infeed speed and direction. The hydrostatic drive system is so refined that the in-feed speed is fully adjustable from 0-75 ft./min. with power in the full range.

Because of its robust weight of the MX-9900ss wood chipper, and to prevent the machine from sinking into the soft ground during operation, the new MX-9900ss offers a wide footprint skid type support base. This skid shoe type base is angled upward on the end like a ski to prevent it from digging into the soft ground use.

A WoodMaxx exclusive and patent pending design. Everyone knows what happens to the branches when they reach the flywheel knives of the wood chipper, but getting the material pulled into the wood chipper knives effectively and quickly is the trick. Many factors must be considered when designing an effective infeed roller system: the overall diameter, knife spacing, tooth angle, type of steel, hardness, down pressure and infeed speed. After countless hours of research and development on the infeed system, for the MX-9900ss we have developed a large diameter (8″) infeed roller. WoodMaxx MX-series auto-feed wood chippers utilize exclusively designed high carbon steel chisel tooth infeed rollers.

This exclusive design allows the chisel shaped teeth of the roller to grab and climb up and over the branches to easily bite in and effectively pull the material into the wood chipper flywheel at speeds up to 75 ft. /min. In short, the larger the roller, the easier it rolls over the material. The smaller the roller, the more likely it is to slip and spin on the branches. Similar to how the small wheels of a shopping cart stop when contacting a small stone in a parking lot. WoodMaxx MX-series auto-feed wood chippers utilize high carbon steel chisel tooth in-feed rollers.

In order to prevent material like tree bark and leaves from impacting between the teeth of the infeed roller, we spaced the chisel teeth out. This spacing allows the complete down pressure of the high tension gas springs to be focused on one chisel tooth at a time increasing total down pressure. Additionally this spacing allows the roller to self-clean. These rollers, along with the high tension gas springs aggressively bite into any type of material. After welding, these rollers are hardened to ensure that the teeth stay sharp for many years to come. The advantage of this type of roller is that is aggressively grabs any size limb with or without leaves up to 9″. Long or short needle pine, as well as small, vine type material is no problem for the WoodMaxx MX-9900ss wood chipper. Small branches, leaves, or vines won’t wrap around the infeed roller as they would on other wood chippers. The exclusive advanced design of our in-feed rollers is a feature that should not be overlooked when shopping for a wood chipper. Our infeed roller designs are so unique and effective that they are now patent pending.

The WoodMaxx MX-9900SS wood chipper is equipped with a 360 degree swivel discharge chute. With easy two finger operation, we have incorporated a convenient handle that effortlessly allows you to swivel the discharge chute 360 degrees so that you can direct the chips into a trailer or the back of a pickup truck without having to move the entire machine. Simply push down on the handle and swing the chute, when you release the handle a spring loaded pin will drop down to lock the chute into position. No tools required.

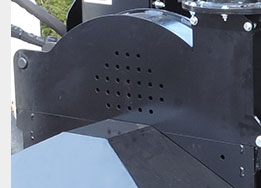

WoodMaxx MX -series wood chippers incorporate a series of precisely located ventilation holes in the flywheel chamber. This feature creates a strong vacuum that draws air into the flywheel chamber, and in combination with the fan blades on the back of the flywheel, forcefully ejects the wood chips out of the chamber. This keeps the discharge chute clear, and reduces the chances of a jam. The WoodMaxx patent pending hole pattern is specifically designed to bring the air into the chamber at the optimal volume and location. Other machines have tried to copy this feature, but have not achieved the same results!

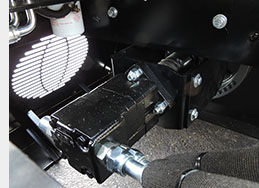

The hydrostatic pump belt tensioner is automatic on the MX-9900ss wood chipper. This feature keeps consistent and correct pressure on the drive belt. If the drive belt is too tight then excessive bearing and or pump failure is likely, too loose and the belt will slip. This feature eliminates the need to adjust the belt, ensures that proper tension is achieved, and increases the longevity of the pump and bearings. It also saves you the hassle of constant adjustment.

All Wood chippers will require some routine maintenance, like adjusting the gap between the bed knife and the flywheel knives as they wear. This gap is essential to proper operation of the wood chipper. The infeed hopper on the WoodMaxx MX-9900 swings open to expose the bed knife. This feature allows the user to access the bed knife (anvil) by opening the hopper to expose the knives. Simply remove two bolts and the hopper will swing open like a door. This feature is exclusive to WoodMaxx, other chippers require the user to crawl into the in-feed hopper to change the bed knife or adjust the gap between the bed knife and the flywheel knives.

The WoodMaxx MX-9900ss wood chipper utilizes JIC (joint industrial council) hose fittings that are rated for 5000 psi. For you this means that if you ever need to replace a hydraulic hose, your local tractor supply or auto parts store can make hoses while you wait. JIC fittings are widely used in hydraulic fluid transfer, the military, and are typically very easy to come by. No trying to chase down an adapter because of mismatched threads.

The WoodMaxx MX-series wood chipper utilizes high tension gas springs. These gas springs maintain the same tension throughout the entire range of motion. This feature also slows and dampens the downward motion of the infeed roller to prevent the infeed roller from slamming downward ultimately increasing the longevity of the components. These high tension gas springs force 175 lbs. of downward pressure that allows the teeth of the infeed roller to dig into the branches and ensure a smooth entry into the chipper head.

California Residents See Prop 65 WARNINGS

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.

Sorry, no reviews match your current selections

© 2022 WoodMaxx Power Equipment Ltd. All Rights Reserved.

Arrived well packaged and secured. Was an easy set-up but definitely want to read the manual as operating speed from magneto seemed to very more than expected. Did a great job handling pine and madrone branches, and fir branches. Did manage to jamb it twice from attempting to feed large short pieces. Was relatively easy to loose chipper throw cowling and clear material. Seems to be quite well made. Truly, my only disappointment with the device is not the devices fault at all…. I had anticipated being able to motor around in CAT CTL 289 and attack various downed branches by myself. But, the CAT expects an operator in the cab to be operating the attachment. Found work arounds to fool the machine into providing hydraulic flow, but it was more frustrating that you want it to be. Still, once my system of weights and magnets was in place, I have been able to keep up on winter falls and thinning of my silva pasture in solo operations, as envisioned. A welcome addition to my farm, and way better to get that carbon working in my pastures than just hauling to a burn pile.

Excellent chipper for my CAT 289d. Chips any 4 inch hardwood or 6 inch softwood diameter or less with ease. Infeed works great. Creates great quality and consistency of chips. I have 20 hours on it and it still chips great with original knives. Highly recommend.

This machine eats all the wood you can feed it! It is the most awesome piece of equipment for our farm and the chips work great in the garden, compost pile and around the blueberries! I couldn’t ask for it to work any better! Thanks!