Subtotal: $268.25

out of stock

FM-78 / FM-78H Flail Mower Y-Blade Complete Set, Inc-(22) Y-Blades, M14x70 Bolts, Nuts) (2015 -Current)

1 × $268.25

FM-78 / FM-78H Flail Mower Y-Blade Complete Set, Inc-(22) Y-Blades, M14x70 Bolts, Nuts) (2015 -Current)

1 × $268.25 Subtotal: $268.25

FM-78 / FM-78H Flail Mower Y-Blade Complete Set, Inc-(22) Y-Blades, M14x70 Bolts, Nuts) (2015 -Current)

1 × $268.25

FM-78 / FM-78H Flail Mower Y-Blade Complete Set, Inc-(22) Y-Blades, M14x70 Bolts, Nuts) (2015 -Current)

1 × $268.25 Subtotal: $268.25

$3,234.00

-

IMPORTANT: Flail mowers purchased with Y-blades are not interchangeable with hammer blades, and vice versa.

$270.75

$270.75

$268.25

$268.25

$25.00

$25.00

out of stock

NSK is a leading bearing and motion control manufacturing company founded in Tokyo, Japan in 1916. Today NSK has several plants around the world including England, Germany, USA and Switzerland and by far one the best quality bearings available on the market today. Although these bearings are very costly, we feel that in an application with high load and dynamic forces such as a flail mower that such high quality bearings are required. These bearings are noticeably smoother, quieter, and cooler running than any competitor and far superior to any no-name brand. Some inferior bearings contain plastic interior ball cages that are susceptible too breakage from shock loads. Poor material and tolerances generate excessive heat that translates into premature bearing failure and even belt wear as the heat travel to the pulleys and the belts. All bearings are not created equal, and this is a feature that should not be overlooked when shopping for a flail mower.

79.5″

74″

710 LBS. (mower weight only) PTO shaft weighs an additional 39 lbs.

30-65 PTO horse power

3/4″ – 3-3/4″ Adjustable to meet various height requirements

4 Gauge .25″ structural Q235 roll formed steel for durability.

1/4″ .250″ Structural Q235 roll formed steel for durability.

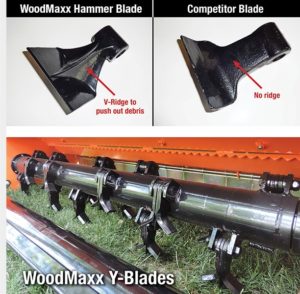

Hammer or reversible Y-blades. Our hammer blades are 40cr, alloy structural steel. (American standard, AISI/SAE/ASTM steel no: 5140) and forged to a tapered wedge shape to avoid material buildup on the blades. Each blade weighs 1.85 lb. (cast steel is much more durable than cast iron) competitors use flat face blades. Side by side comparison of WoodMaxx exclusive hammer blade design: The reversible Y-blades are made from .33″ 60si2mn, spring steel, (American standard: A29m) formed, heat treated, and quenched in oil and weigh 1.75 lb. each. Use the hammer blades for clearing saplings (1″ diameter or less), and the Y-blades for grasses.

22 Hammer or 44 Y- blades w/ 22 ctr blades between the Y (WoodMaxx exclusive)

The blades are staggered precisely with no gap in the mowing area. Blade overlap is important to achieve an even cutting result.

This allows for easy inspection, cleaning, blade changing, and maintenance of your machine. The rear gate can also be left open for easier discharge in heavy conditions, or you can close the gate to greater mulching.

The rotor spins in the opposite direction as the wheels of the tractor when traveling forward. This allows the blades to shear the material as it is folded forward by the mowers. The material is then thrown up and over the rotor.

4.25″- Heavy duty 5/16″ wall tubing for long life.

The rotor tube is balance to reduce vibration and ensures that the mower runs smooth, and reduces wear on the bearings.

The V-belt pulleys are heavy duty cast iron and balance to eliminate vibration, and run smooth.

Large swing so that the blades build required inertia.

2160 RPM

128 ft./sec – High tip speed = efficiency to cleanly cut material

Category 1 standard 3 point or category 1 quick hitch – will attach to any cat 1- 3 point hitch and will also work with cat 1 quick hitch (except John Deere I-Match)

This feature allows for offset from center to the right of the tractor. This feature is helpful for mowing around fences, buildings; walkways etc. From the center of the PTO the mower extends 46″ to the right and 33″ to the left.

Three Total B-Series USA gates “truflex” – we use only USA made gates belts on our flail mowers for long life. (easy to find SAE standard belt size BX39)

Solid state automatic – this feature automatically adjust the belt tension so you don’t have to worry about slippage or overworking the belts. This feature greatly increases the belt life.

540 ONLY

Up to 55 hp. Heavy duty proven oil bath gearbox for long life.

Cast iron 540 RPM with internal over-running clutch – when the PTO shaft is disengaged the built in over running clutch allows the PTO shaft to stop turning while the gearbox and rotor shaft slow down gradually. This is an important feature, without it, the gearbox will slam to a halt when the PTO is disengaged, causing stress to the gearbox and your tractor. This feature should not be overlooked when shopping for a mower.

The skid shoes reduce gouging are bolt on so you can adjust or replace them easily when the time comes.

1-3/8″ 6 spline w/slip clutch.

Accessible greasable bearings for easy maintenance.

5.25″ With tapered ends – this roller contacts the ground to ensure even cutting height. The ends of this roller are rounded to eliminate gouging when turning corners. A scraper bar ensures that mud and debris buildup is cleaned off as you go.

The rust resistant baked on powder coat finish is more durable than conventional paint to keep your machine looking good for years.

A robust machine with an equally robust warranty.

At WoodMaxx our service department is staffed with professional certified technicians that inspect each machine before it is shipped. This ensures that you get a trouble free machine from the get go. When you need technical help or parts, our courteous staff can help you get what you need from our fully stocked warehouse.

California Residents See Prop 65 WARNINGS

-NSK BRAND SHAFT BEARINGS

-79.5″ Overall Width

-74″ Cutting Width

-Requires 30-65 hp PTO

-3/4″ – 3-3/4″Cutting Height

-1/4″ Structural Q235 Structural Side Plate

-Optional Duck Foot (Hammer) or Reversible Double Y-Blades

-Reverse Rotor Rotation

-4.25″ Rotor Tube Diameter

-13.5″ Rotor Swing Diameter

-2160 RMP Rotor Shaft Speed

-Blade Speed 128 Ft./Sec.

-Cat. 1 Hitch Type Only.

-Three (3) Total B-series USA gates “truflex”

-Automatic Drive Belt Tensioner

-Replaceable Skid Shoes

-1-3/8″ 6 spline w/slip clutch (included)

-Removable rakes

-2 Year Parts Warranty

-Shipping Dims: 82x35x29 (Due to increased gas prices and size/weight of this machine, additional shipping charges may be incurred.

-Shipping Weight: 900 lbs.

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.

Sorry, no reviews match your current selections

© 2022 WoodMaxx Power Equipment Ltd. All Rights Reserved.

Very happy with my purchase. Delivered on time and in perfect condition. Setup was easy and even when I had a question, I called and they gave me the answer straight away…excellent support.

Ran it for the first two hours cutting my field…love it. I have the grass cutting knives and I love the finish they leave. Had been cutting this field with a brush hog – I like this so much better. Still use the brush hog for stuff that’s a bit more knarly, but for my fields this cut is amazing and just what I was looking for.

This is a great machine. Very well built.

I’ve been cutting chest high grass/weeds in my fields and it has done a great job. I’ve also mowed my field edges and the finish is much better than the old rotary cutter I was using.

I put hammer blades on mine and I think they cut better and would recommend them.

I’m very happy with my FM-78.

Started mowing with my FM-78 a couple weeks ago. It is a great machine. Very well built.

Does a much better job of mowing my fields than the old rotary cutter I was using. WoodMaxx was out of the FM-78 with hammer blades so I had to buy the machine with Y-blades and order a set of hammer blades extra. I cut some of my fields with the Y-blades before the hammers came (they were backordered). I put the hammer blades on and have been cutting with them. I think they do a nicer job and they cut better in high (waist high) grass and recommend using them.

Great machine.

Received the 78 flail mower and removed it from the semi trailer using our tractor palette forks, and marveled at the shipping crate’s beauty and strength, a sign of the care, quality, and beefiness of the mower itself. Cutting the PTO shaft took an hour with a sawsall and file/grinder. When we went to install the top bracket for the 3pt hitch, the brackets on the mower needed to be adjusted inward so the top bracket holes could meet up with the ones already on the mower, no big deal, they are slotted. We removed the front sections of the shipping crate and hooked it up to our 3725 Branson, easy peasy. Once I could move it around a raise it as needed, I greased every Zerk and filled the gearbox with synthetic 75-90W Mobile 1 lube. To lube the roller Zerks I opened the back hatch and marveled at the rows of thick heavy hammers.

I took it out for its first cut later in the day, and it was soo smooth and easy to use, lifting it occasionally when navigating over a ridge or ditch to avoid stressing it. I love the wide cutting path and evenness of the cut compared to the 5 foot rotary cutter I had been using for a few years, junk comparably.

Over the years, I’ve removed most loose rocks from our field of over 20ac, but it did hit a couple of lemon sized ones while doing a smaller area, (it takes hours and hours to cut our entire field area). Anyway it tossed them 15 feet in front of the tractor, so I learned a little lesson, not only is there some danger from behind, but also in front. It does kick up a bit of dust on really dry soil, so I will probably wear a mask if the dust is too much on some days.

So far it has been a joy to use and does a beautiful job, very pleased with the quality and beefiness and ease of use.

I received my FM-78 after I needed (Not Woodmaxx fault). It came in a neat package; took a couple of hours to assemble including sizing the PTO. Assembly was easy and directions were good.

The main reason I bought the FM-78 is one of my customers is a Rail Trail group and I mow 64 miles of the trail. The FM-78 did a fabulous job and my client was so impressed with the quality of the cutting. I have hammers on mine because I mostly mow mixed grass and brush.

My NH 192O with 33 hp runs the mower well most of the time. In dense grass I need to take it slow. Again this isn’t Woodmaxx fault. It performed great on the rail trail now I am trying to figure where I use it and where I use my bush hog.

The FM 78 is built well and is rugged. I have about 100 hrs on it a couple of bolts lossened up but it is work; just check things out. I have sharpened the hammers 3 times. I do this with the hammers on the flail. Takes 30-45 min; this includes checking the bolts are tight.

All in all very pleased with my FM-78, the price is very reasonable for the quality and I recommend buying on.

Shaun B

Hill, NH