out of stock

$3,135.00

-

$155.00

Out of stock

$155.00

$200.00

Out of stock

$200.00

$25.00

$25.00

out of stock

out of stock

The WoodMaxx WM-8M mechanical auto-feed chipper is a robust self-feeding PTO driven wood chipper attachment that mounts to the 3-point hitch of your tractor. This PTO wood chipper is compact, yet built to withstand commercial use. High quality made-in-the USA knives are standard equipment on all WM-series wood chippers. The WoodMaxx WM-series chippers are so unique and innovative that they are now patent pending. Attempts have been made to copy this machine, but there is only one WoodMaxx! Check out these features.

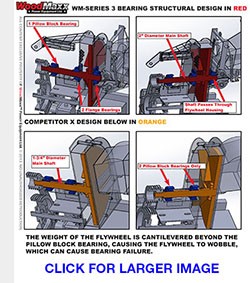

WoodMaxx WM-series wood chippers are the perfect combination of size, weight, and features. Compact enough to easily move around, yet strong enough to get the tough jobs done. WM-series chippers are loaded with features typically found on much larger commercial machines that are much more expensive. The strength of our machines start with using heavy formed Q-235 (American standard A-36) structural steel plate; the strongest plate steel available. Each piece is CNC plasma cut, and meticulously welded. WoodMaxx WM-series chipper exclusive structural design includes a 2″ diameter main shaft that passes through the flywheel housing and is supported by 3 bearings: 1 pillow block and 2 flange bearings. This feature, combined with the 2″ shaft, allows the flywheel to run true and ads a great deal of strength. This design sets WoodMaxx chippers far apart from the competition, and it is a design feature you should not overlook when shopping for a chipper.

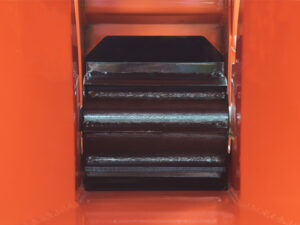

Another WoodMaxx exclusive! Designed by WoodMaxx, copied by some. We all know what happens to the branches when they reach the flywheel, but getting the material to pull into the chippers quickly and effectively is the trick. Many factors come into play when designing an effective in-feed roller: the overall diameter, blade spacing, tooth angle, type of steel, hardness, down pressure and speed. After countless hours of R&D on the in-feed system, we have developed a large diameter (6.25″) in-feed roller that easily climbs up and grabs the branches to bite in and efficiently pull the material into the flywheel at up to 58 ft./min. The larger the roller, the easier it rolls over the material. The smaller the roller, the more likely it is to slip and spin on the branches. We equate this to the small wheels of a shopping cart stopping when it contacts a small stone in the parking lot. WoodMaxx auto feed wood chippers utilize in-feed rollers with high carbon steel chisel teeth. This type of in-feed roller is found on larger, much more expensive machines.

We have also spaced the teeth out to prevent material like leaves and bark from getting impacted between the teeth. This allows the roller to self-clean, and also allows the 165 lbs. of down pressure to focus on fewer teeth which increases the bite. These rollers, along with the high tension springs aggressively bite into any type of material. After welding, these rollers are induction hardened to ensure that the teeth stay sharp for many years to come. The advantage of this type of roller is that is aggressively grabs any size limb up to 8″ with or without leaves. Small, vine type material as well as long or short needle pine is no problem for the WoodMaxx WM series chipper. Vines, leaves, and small branches won’t wrap around the roller as they would on other chippers. The advanced design of our in-feed rollers is a feature that should not be overlooked when shopping for a wood chipper. Our in-feed roller designs are so effective and unique that we now have patents pending.

The infeed system on the WM-8M utilizes a belt driven oil bath heavy duty gear box that increases torque and transfers power to the upper feed roller through an extreme duty drive axle. For long life, the drive axle is machined splined (similar to the PTO spline of your tractor), and the U-joints are protected from debris by a rubber boot. The clutch mechanism is precisely machined from solid steel to ensure proper function. This in-feed system will feed material at a rate of 58 ft./min.

All WoodMaxx WM-series chippers are now category 1 quick hitch compatible. WoodMaxx is the only PTO chipper that works with quick hitch (**John Deere I-match/Land Pride QH10 & QH05require a special top link that we make for this purpose, please call to specify if you need this). Save time by never leaving the seat of your tractor to link up with the WM-series chipper. Attaching the chipper to your quick hitch takes only seconds. Please note, you’ll need the Premium PTO shaft or a longer imported PTO shaft if you have a quick hitch (contact us for more info). Check out our video tab to see the quick hitch in action! No quick hitch? No problem. The chipper will easily attach to a standard 3pt hitch, just back in and insert the pins. No need to force the draw arms of your tractor around the draw pins (as with many other implements)

360 degrees of rotation and 2 finger operation. We have incorporated a convenient handle that effortlessly allows you to swivel the discharge chute so that you can direct the chips into the back of a truck or trailer without having to move the entire machine. Simply push down on the handle and swing the chute. When you release the handle a spring loaded pin drops down to lock the chute into position. No tools required.

Because of its robust weight and to prevent the machine from sinking into the soft ground during operation, the new WM-8H offers a wide footprint skid type support base. This base is angled upward on the end to prevent digging into the ground while transporting.

WoodMaxx WM-series wood chipper attachments incorporate a series of precisely located ventilation holes in the flywheel chamber. This feature creates a strong vacuum that draws air into the flywheel chamber and in combination with the fan blades on the back of the flywheel forcefully ejects the chips out of the chamber. This keeps the discharge chute clear, and reduces the chances of a jam. The WoodMaxx patent pending hole pattern is specifically designed to bring the air into the chamber at the optimal volume and location. Other machines have tried to copy this feature, but have not achieved the same results!

Three heavy duty cast steel bearings support the main shaft, which passes through the flywheel housing, and is supported on either side by flange bearings. This heavy duty, shock resistant cast steel bearings are much more durable than cast iron – a unique feature of the WoodMaxx chipper.

The WoodMaxx WM-series chipper utilizes high tension springs in conjunction with a unique adjustment mechanism that offers a full range of variable down pressure, since all branches are different – some soft and some hard. This feature allows the user to increase to decrease the upper roller down pressure to suit the situation. Crank up the tension to achieve up to 165 lbs. of down pressure. This allows the teeth on the roller to dig into the branches and ensure a smooth entry into the chipper head.

WoodMaxx WM-series chippers are equipped with extreme duty 5/8″ wide cogged drive v-belts. Cogged v-belts run cooler, and transfer more torque than plain smooth v-belts. Although the OEM belts are very high quality, if the need arises, the standard BX size allows you to purchase replacement v-belts at any auto parts store. Other chippers use 15mm belts – try to find those in the USA!

Safety is paramount on WoodMaxx chippers. Located on the top of the in-feed bin, the WoodMaxx 8″ PTO chipper utilizes an easy to activate auto-feed stop safety bar to disengage the in-feed rollers in case of an emergency, or to clear the in-feed bin if necessary. This safety bar can be actuated and left in the off position, hands free, so that the operator can use both hands to clear the in-feed bin. This feature is safer because it allows the user to start the chipper without the feed rollers turning. Other chippers require a hand on the safety bar to keep the feed rollers in the off position.

WoodMaxx chippers come shipped to you in a steel crate and are almost completely assembled. Simply attach the in-feed bin, discharge chute, PTO shaft (included), and attach to your tractor. All WoodMaxx chippers are given a comprehensive 22 point inspection, and are serviced prior to leaving our warehouse. The drive belts have been aligned and tightened, knives have been installed, adjusted, and torqued down, and bearings have been greased. These and other steps performed here greatly reduce assembly time on your end. Just follow the illustrated, American written, user friendly assembly manual (and watch the video), and you will be up and running in about 2 hours.

You asked for it and we delivered! In 2012 WoodMaxx developed the first adjustable chipper base legs. These adjustable legs will help accommodate a larger variety of tractors. This innovation allows you to more easily meet the required PTO shaft angle (less than 15 degrees) on larger tractors. Simply insert the adjustable legs, and then slide the pin into the hole for your required leg height. WoodMaxx PTO wood chippers are able to accommodate tractors that have a PTO height from 18″ to 30″ high.

The 2″ main shaft on the WM-series PTO wood chippers passes through the flywheel housing and is supported by 1 pillow block and 2 flange bearings. This feature, combined with the 2″ shaft, allows the flywheel to run truer, and adds a great deal of strength. Other chippers use a 1-3/4″ shaft, 2 pillow block bearings, and the flywheel is cantilevered beyond the bearing. With this setup, there is a possibility of breaking a bearing housing the machine jams.

WM-8M… 950lbs (shipping) Steel crate dimentions are L=46″ x W=36″ x H=48″

More weight = more steel

More strength and stability… period.

WoodMaxx WM-series wood chippers are equipped with an adjustable bed knife to ensure that the proper knife gap is achieved. This feature allows the user to adjust the distance between the flywheel knife and the bed knife so that the required distance is maintained after knife sharpening. Proper gap is important so that even the smallest material is chipped as it passes through the chipper.

The infeed hopper on the WM-series wood chippers is horizontal and approximately table height for easy material loading.

The powder coat finish is baked on at 450 degrees, and is thicker and more durable than ordinary paint.

WoodMaxx wood chippers include a standard PTO shaft, but we do offer a very high quality Premium PTO shaft.

WoodMaxx chippers are extremely robust, and can handle heavy use. Designed in upstate New York, each machine we offer is thoroughly tested on our 18 acre proving grounds before being offered to the public. With years of experience and thousands of machines in service today, we are confident that this machine can handle even the toughest projects that you have. Our machines are currently in service in several commercial applications, such as: the Army Corps of Engineers, college campuses, municipalities, tree farms, golf courses, apartment complexes, and thousands of residences. WoodMaxx wood chippers are also represented around the globe, with machines as far away as Hawaii, and Alaska, as well as several countries including: Chile, Russia, Panama, Colombia, Poland, United Arab Emirates, Israel, West Africa, Greece, Norway, Iceland, Ecuador, Honduras, Ireland and of course Canada.

Do not be fooled by imitators. WoodMaxx is the original chipper of this design. We have spent hundreds of hours designing and testing to create this machine. WoodMaxx offers the highest level of quality and innovation with many exclusive features not found anywhere else. Cheap knock-offs do not have the quality workmanship and history of satisfied customers that WoodMaxx has. Just compare our reviews to those of the competitors, and you can see for yourself!

At WoodMaxx our service department is staffed with professional certified technicians that inspect each machine before it is shipped. This ensures that you get a trouble free machine from the get go. When you need technical help or parts, our courteous staff can help you get what you need from our fully stocked warehouse.

California Residents See Prop 65 WARNINGS

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.

Sorry, no reviews match your current selections

© 2022 WoodMaxx Power Equipment Ltd. All Rights Reserved.

First, my tractor is a Massey Ferguson 231, 34 horse PTO. This chipper is a beast. Warning labels all over this unit, so that makes it super cool. I didn’t read the manual any further than assembly so if any of my experience is covered there I apologize. I used this thing for 10 to 12 hours a day for a week. I found the first couple days the mechanical in feed kept getting clogged. I finally noticed that the cotter pin on the left side of the in-feed arm was missing, and the arm was moving with the wheel and spring instead of holding fast. I made the repair, and it started working like a champ. This unit will handle 8-inch wood, but it struggles with hard wood if it’s that large. Another issue I had was with the discharge chute. Mine actually clogged full. I’ve been running mostly pine, so I guess the sap acted as a glue. I have run large limbs through this unit, that had smaller limbs on them. I learned the chipper works best if you have that type of thing to cut them off first. I am extremely satisfied with my chipper. As I said, this thing is a beast.

Woodchipper arrived in mostly new condition only a few minor dings and scratches. After three days of rain I was able to put it together to find out they sent me a used broken PTO shaft. I contacted customer support twice and after several days was told the person who could help me was out of the office the rest of the week and the following week was the 4th of July so nobody could help me until after the 4th. I have since then been ignored or sent to their warranty guide for any form of compensation. After two weeks of having the woodchipper attached to my tractor I randomly received a new PTO shaft and the set up works great. Leaving 1 star due to the horrible customer service experience and the refusal of any kind of compensation for wasting two weeks of my time and missing our on several jobs.

I would like to thank the shipping team for working with me on getting my chipper 3 hours closer to me sending it to my local fedex freight terminal where I picked it up.So far so good it works great on my Lx 2610 also my neighbor and I made chip hopper from shipping crate and have filled it four times and around our property thanks again

I bought this wood chipper a couple of months ago. It has exceeded my expectations, and has done an incredible job chipping up large limbs. I wasn’t exactly sure what to expect, but this has been a must have to clearing my property. I couldn’t recommend this product enough!

The recent ice storm in February damaged so many trees that purchasing a chipper was necessary. I ordered the WM-8M chipper. Solid piece of equipment and fits on my JD 3203 very nicely. Been using it for 3 weeks now chipping cedar and oak, 6″ cedar is no problem, keep the larger oak for firewood, and chip the rest. This machine past my expectations, very well built, easy to put together, and can keep a continuous feed of wood going into it. Yes, its a beast and will keep you busy feeding it. I have 5 acres with loads of cedar and oak to keep me occupied. Now I can drive to where the trees are and chip right there without dragging limbs. Delivery was in a week and when it arrived, the driver had just unloaded another Woodmaxx chipper a short ways from me. This is the chipper you want from Woodmaxx .